Air to Water heat pumps

Residential Monobloc heat pumps for Heating and Cooling with integrated plant management system and remote control via an App.

View details

Central heating module for heat pump systems

Discover Eco Hydro Kit combined with MIRAI-SMI 4.0 heat pump!

View Details

Sustainability

Sustainability is part of our DNA.

View details

Discover how we’re determined to make a difference.

Residential air conditioners

The new X-REVO R32 product range stands out for its efficiency, quietness, and air quality.

View details

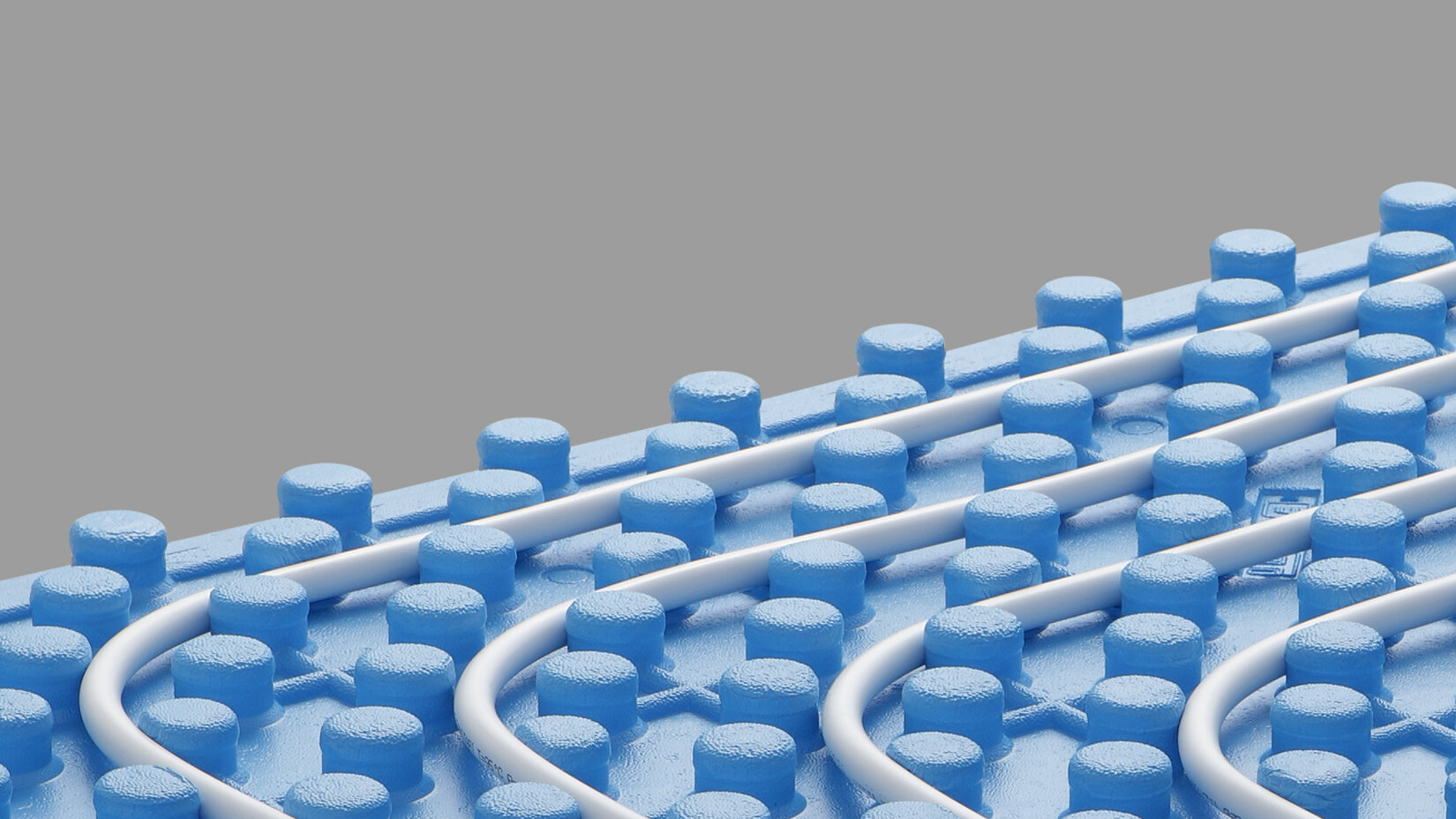

Underfloor heating and cooling systems

Emmeti Floor - The most pleasant and safe way to use the floor as a heating and cooling system in the winter and summer.

View details

Multilayer distribution system

Emmeti Gerpex's hot, cold, and heating water distribution system offers excellent dependability and durability.

View Details

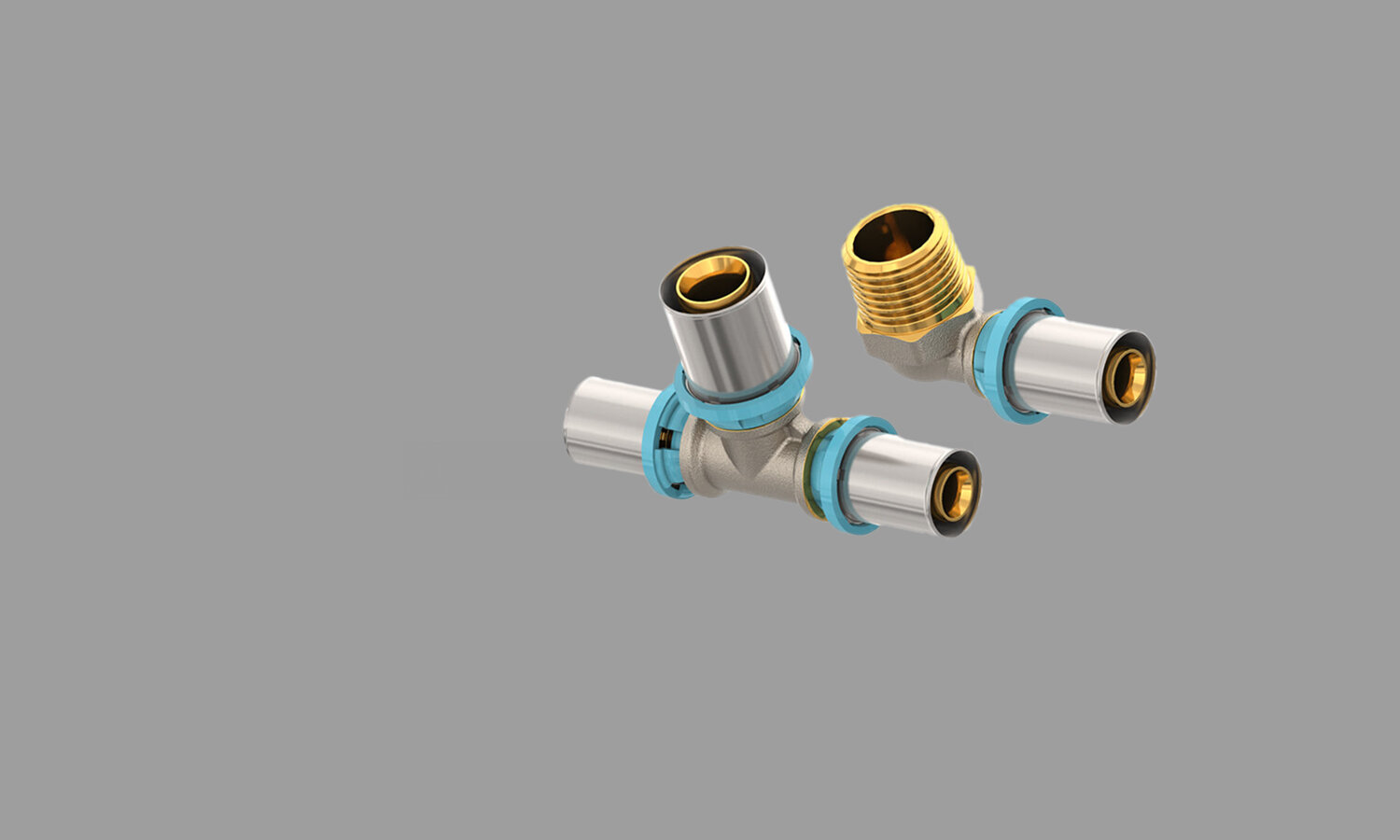

Water press fitting with Leak Before Pressed feature

Gerpex LBP - The press fitting for Emmeti multilayer pipe, developed to assure a water leakage when the fitting is not pressed.

View details

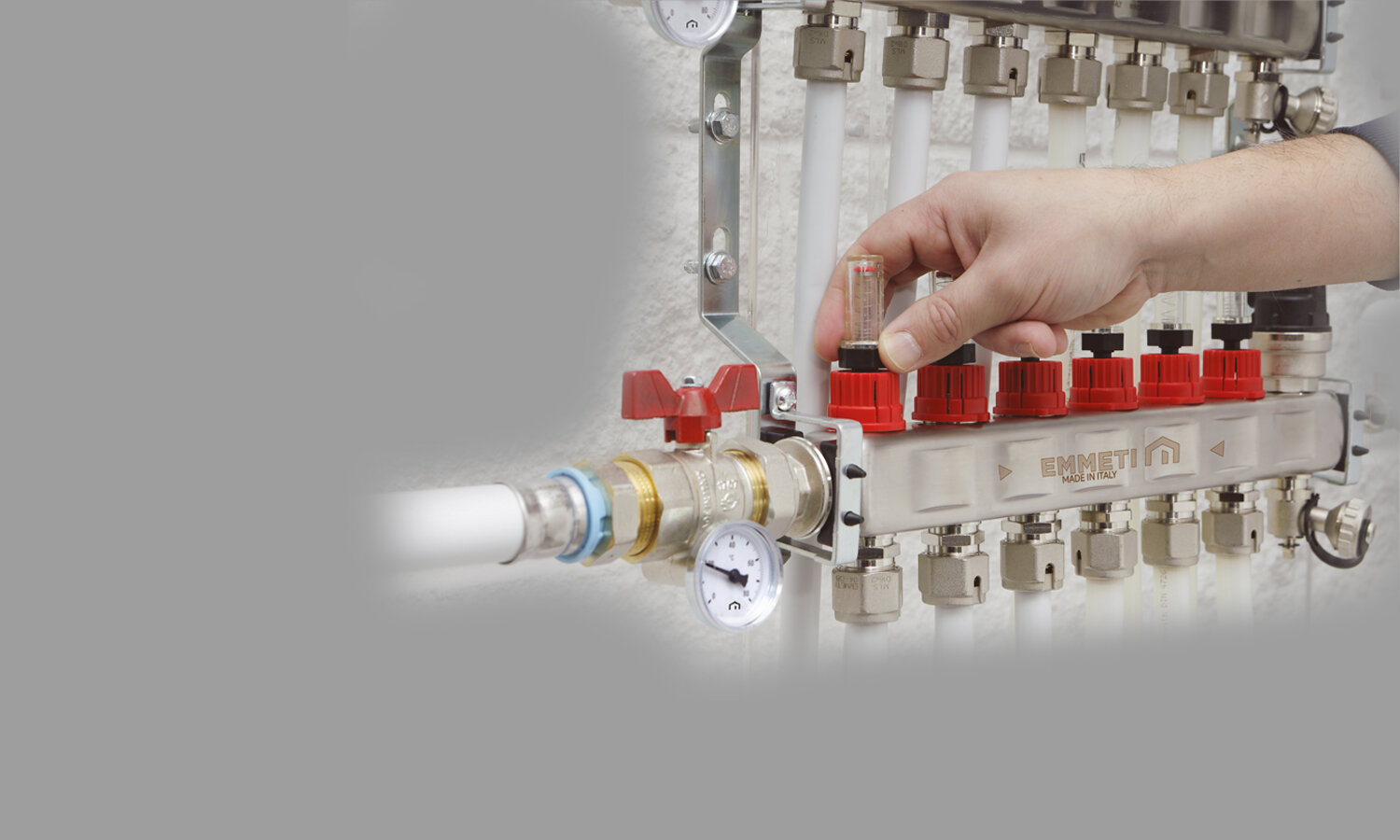

Stainless steel manifolds

Topway S - The stainless steel distribution manifold for heating and cooling systems

View details

Emmeti, your partner in plumbing, heating, and air conditioning

Innovative products that are easy to install, designed for the consumer, and made for the installer

Emmeti has been delivering progressively full and innovative solutions in the plumbing, heating, and air conditioning industry since 1976.

Emmeti is one of the most comprehensive enterprises in this industry due to its ISO 9001-certified manufacture of ball valves, radiator valves, brass fittings, and multilayer pipes.

At Emmeti, we have a strong belief in a new way of living where technology and respect for the environment work together to promote human health and well-being.

We are driven by the desire to provide comfort in residential and commercial spaces; thus, we pay close attention not only to energy conservation but also to the environment, and the ISO 14001:2004 Environmental Certification confirms this commitment.

Emmeti Systems: 360° proposals for complete solutions

Living in healthy, comfortable, and environmentally friendly places is becoming increasingly vital.

Emmeti, strengthened by know-how gained in nearly fifty years of activity in the fields of thermohydraulics, air conditioning, and renewable energy, is the best guarantee in the proposal of integrated and reliable systems to heat, cool, and power your home while respecting the environment and saving energy.